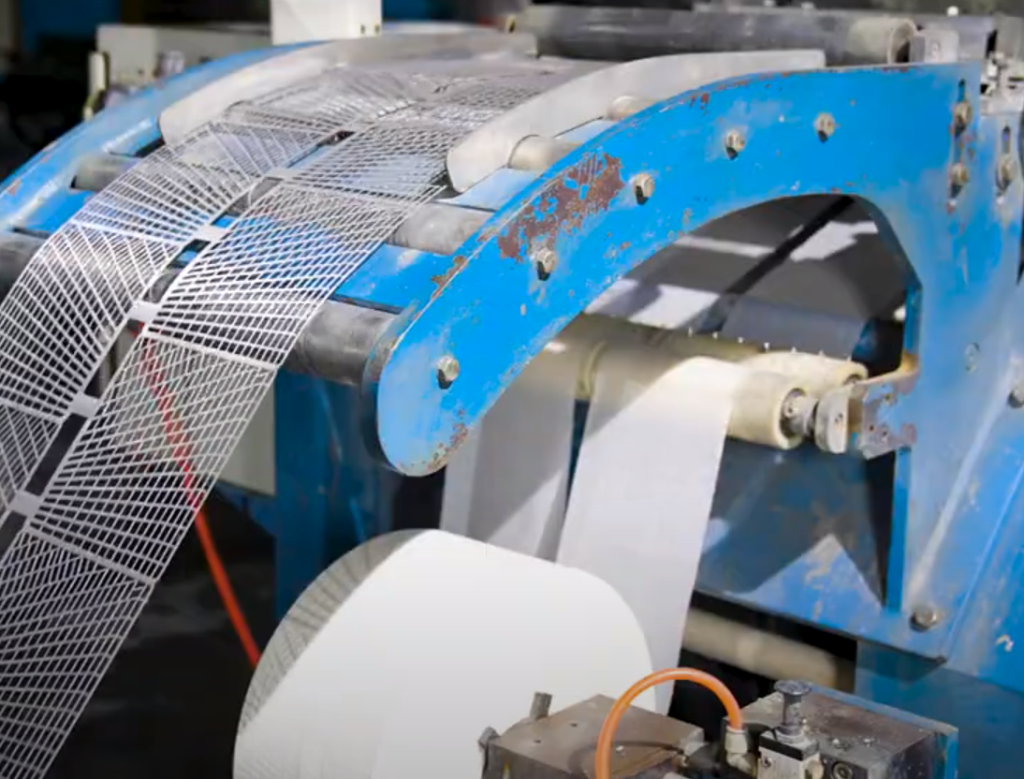

Lead acid batteries are commonly used in various applications, from automobiles to backup power systems. These batteries rely on a process called pasting, which involves applying a mixture of lead oxide and sulfuric acid onto the battery plates. One crucial component in the pasting process is pasting paper.

Pasting paper is a specialized material that acts as a separator between the lead oxide paste and the battery plates. It serves multiple purposes, including:

- Absorbing excess sulfuric acid, helping to maintain the proper acid concentration in the battery.

- Facilitating the adhesion of the lead oxide paste to the plates, ensuring a consistent and reliable bond.